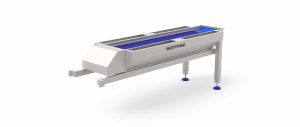

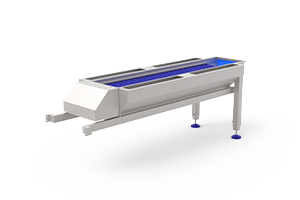

Onion peeler USM-S100

By means of a singulating chain the onions are transported from the infeed hopper and positioned onto the flights of the transport chain. The operator places the onions in the right horizontal position. The rotating knives top, tail and cutting arms make a horizontal cut around the onions.

At the end of the conveying section the onions are picked up with a double holding-arm system with rotating holders.

For adapting the machine to different onion diameters several adjustments are provided. These can mostly be made from outside, even during operation, by means of a hand wheel.

The Sormac air saving technique which is used in the USM-S100, takes care of low energy consumption in combination with a higher peeling quality.

Product specification

The USM-S100 can peel onions with a diameter of 2 1/8” – 4 11/16”. For smaller and larger diameters adjusted executions can be supplied (see options).

Capacity

Depending on diameter, shape, and quality the USM-S100 onion peeler can handle up to 4,800 – 6,000 onions per hour, positioned by one person.

Features

|

Energy and air saving technologyUp to 40% lower energy and air consumption levels than similar machines. |

|

Ergonomic design at one levelThe machine was designed to be on one level so as to make working with, and adjusting, the machine as easy as possible for operators. |

|

Low sound pressure levelDuring production < 83 dB(A). |

Options

|

Directly mounted inspection table |

|

Operating platform |

|

Waste transportation screw conveyor |

|

Conveyor chainsFor non-standard onion diameters (1 1/2″ – 2 13/32″ or 3 3/16″ – 5 7/16″). |

Onion peeler USM-S100

Specifications

| Type: | USM-S100 |

| Voltage: | 230/400 V, 50/60 Hz |

| Installed power: | 2.3 kW 3.1 HP |

| Dimensions (L x W x H): | 5,540 x 1,120 x 2,125 mm / 18’-2.3” x 3’-8.1” x 6’-11.7” |

| Air pressure requirement: | 6 bar (dry air) (87 psi) |

| Air requirements: | max. 1.1 Nm³/min (39 cfm) (at 6 bar air pressure) |

| Noise level: | < 83 dB(A) |